Onboard Design:

Optimization of Human–Boat Interaction

Onboard Design is about supporting teams, skippers, architects, and builders in the conception and optimization of racing yachts.

The primary goal is to adapt the boat to human specificities, maximizing performance and sustaining effort over long periods of time.

The Importance of Ergonomics on an Offshore Racing Yacht

In racing, every gesture of the skipper has a direct impact on performance. A poorly positioned hydraulic button, for example, can result in an unnecessary movement repeated hundreds, even thousands of times. If the entire cockpit is affected, the skipper will spend their time fighting against the machine—an easily avoidable loss of performance.

Onboard Design helps detect friction points between humans, hardware, and the boat itself. It supports co-creating solutions with teams and integrating ergonomics right from the earliest design phases.

Expertise includes:

Ergonomic optimization of the cockpit

Collecting and analyzing viable human data to support design office decisions

Leading multi-stakeholder workshops (skippers, designers, engineers,…)

Co-design of rest and living areas

Optimizing the use of full-scale mockups with dedicated design tools (VR/AR)

Methods & Tools

Video analysis of maneuvers onboard and in VR

Data analysis from onboard systems

Collaborative workshops. With the possible use of mockups, user feedback, and real-world testing

Field interviews and direct observation

In-situ iterations

Virtual Reality (VR) for decision-making support, team alignment, and mixed-reality integration with full-scale 1:1 models

Collaborative tools enabling fast, collective decision-making and efficient solution validation

Case Study: Video Analysis

Video analysis makes it possible to extract reliable data on the skipper’s positioning and the actual usage time of onboard equipment.

The goal is to identify the main energy consumers. For example, if a winch is used 90% of the time, improving its efficiency by just 5% will have a far greater impact than optimizing another system that is only used 3% of the time.

This approach helps target optimizations where they will deliver the most performance gains, reducing maneuver time and improving overall energy efficiency.

The following example is purely illustrative and does not come from an actual commissioned study (as past projects are under NDA). The video was chosen without any prior selection, simply the first available on YouTube: “Au cœur du cockpit de PAPREC ARKÉA | Vendée Globe 2024”.

Reference videoclip:

This short video shows a navigation phase in the cockpit of an IMOCA.

The skipper trims and tensions a line, then prepares the grinder. Almost immediately, even without in-depth analysis, we can see he is hindered by his watch cushion. A significant part of his maneuver involves moving it twice—it simply won’t stay in place.

This seemingly minor adjustment, repeated a hundred times, could account for around 6% of his daily caloric expenditure.

It would be valuable to ask him why he needs this cushion, as well as an additional watch seat. Perhaps the two are redundant, or perhaps each only works for a specific use case. Either way, his feedback would likely make it possible to optimize the layout and cut maneuvering time in half.

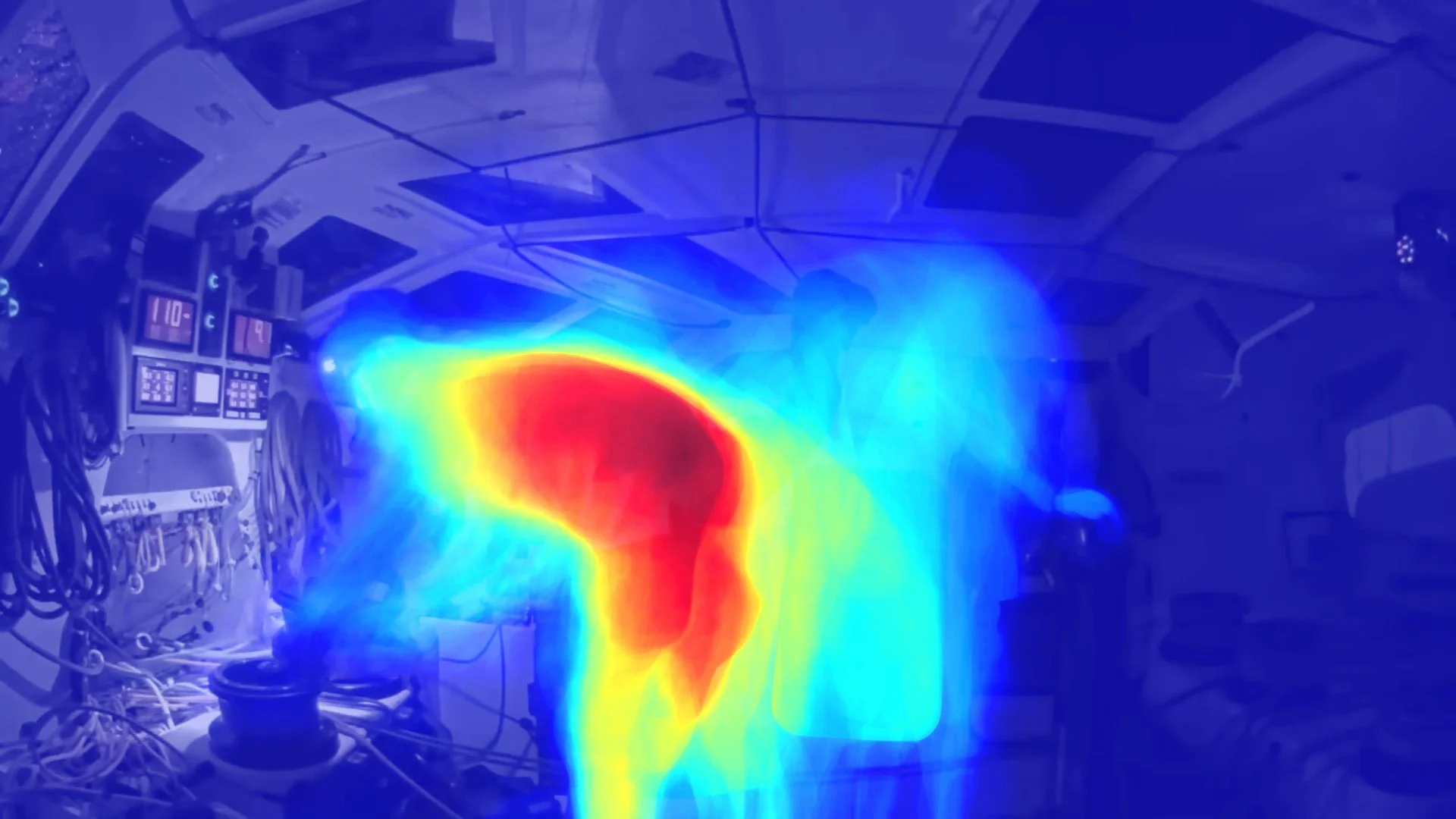

Heat map “Areas”

Heatmaps helps visualizing performance constraints

Heatmaps are powerful visual tools that help analyze and interpret the skipper’s movements and behaviors on board. Position heatmap made using the last sample videoclip shows in red highlights the areas where the skipper spends most of their time, while blue indicates zones they never use. This visualization makes it easy to identify hotspots of activity, flow zones, and wasted space.

The heatmap analysis from the reference sample shows that the skipper spends a large share of their time moving between the winches and the grinder. The frequent posture of bending forward at a 90° angle toward the winches reveals an ergonomic issue: a roof that is too low and winches placed too low.

This posture can cause a significant energy loss (around 66% compared to an ideal position, amounting to thousands of kilocalories wasted over the course of a race.) It also prevents the skipper from delivering their full muscular potential, ultimately reducing overall performance.

Hand Heatmaps: optimizing micro-movements

Hand heatmaps provide a detailed visualization of the skipper’s hand movements, revealing not only the most frequent contact points but also the invisible paths traced during maneuvers. The video shows that the pedestal grinder and the winches are directly linked by a recurring trajectory, which the algorithm makes visible.

By shortening this path by even a few dozen centimeters bringing a winch closer or adjusting its height, the time and effort required for each action can be cut significantly. Over the course of a race, these micro-optimizations add up: a few seconds saved per maneuver, multiplied by hundreds of repetitions, translate into valuable minutes gained, significantly reduced fatigue, and potentially more maneuvers/sail trim adjustments executed.

Hands heatmap

Time Tracking: prioritizing by frequency of use

Measuring the time each piece of equipment is used makes it possible to position every winch, grinder, or clutch intelligently according to its frequency of operation. A frequently used element should be prioritized over others to ensure easier, more efficient access.

In this very short video sample, we can see that the port-side winch is used 35% of the time, primarily for trimming, while the grinder accounts for 21%, often serving as a handhold. (time data visible in the top left of the video). The other winches are barely used within this sequence and, if this sample is representative, they could be considered low-priority or even unnecessary in terms of positioning.

Hardware time

Co-creation VR/AR

The collaborative approach enables a seamless integration of ideas from all stakeholders. With VR and AR, users without CAD expertise can make meaningful contributions to the design process. This method makes it easy to capture sailors’ insights and translate them directly into design environments such as Rhino, NX, SolidWorks, or CATIA.

Training & Testing in Virtual or Physical Environments

Co-creation through VR, AR, and full-scale mockups enables both training and testing in virtual and physical environments. This approach makes it possible to refine boat design and ergonomics by simulating real-world conditions.Whether in advanced simulators or simplified mockups.

Complementary video analysis tools capture and assess skipper movements, both in virtual setups and on physical models.

This allows teams to quantify navigation phases, evaluate the effectiveness of design changes, and guide improvements well before launch.

Turning Ideas into Tangible Solutions

In a user-centered design approach, prototyping plays a crucial role. It’s about moving quickly from abstract concepts to tangible representations, even imperfect ones, in order to better understand, test, and evolve ideas.

The “monster” prototype embodies this philosophy: rough, deliberately unfinished, and focused not on beauty or polish, but on exploring usage. It serves to test hypotheses by confronting ideas with real human and technical experience.

We help bring these prototypes to life using the most efficient processes for each need, maximizing speed, relevance, and cost-effectiveness.

From a cardboard mockup sketched out during a meeting, to a full-scale plywood model, or a precisely machined titanium part, every prototype is built with one goal: to generate precise, actionable feedback directly usable in the design process.

To further accelerate testing and validation cycles, we also provide dedicated 3D printing services (both conventional and carbon-fiber reinforced).